<div class="pull-right">https://steemitimages.com/DQmb5QEm9UPTzctD9zgv6MzAtaTvT3aHkX1XSVMbpHCfXVm/image.png</div>

Coking is an energetic form of thermal cracking used to obtain direct distillation gasoline (coke naphtha) and various intermediate distillation fractions, which are used as catalytic cracking materials. By this process, the hydrogen in the hydrocarbon molecule is reduced so completely that the residue is an almost pure form of carbon, called coke.

# Delayed Coking

In delayed coking, the material is first loaded into a fractionator to separate the lighter hydrocarbons and then combined with the heavy recycled oil. The heavy material passes to the coking oven and is heated to high temperatures at low pressures to avoid premature coking in the heater tubes, thus producing partial vaporization and gentle cracking. The mixture of liquid and vapor is pumped from the heater to one or more coke drums, where the hot material remains about 24 hours (delay) at low pressures until it decomposes into lighter products. When the coke reaches a predetermined level in a drum, the flow is diverted to another drum to maintain the continuity of the operation. The steam from the drums is returned to the fractionator to separate the gas, naphtha and gas oils, and recycle the heavier hydrocarbons through the furnace. The delayed coking unit converts the vacuum residue to gas, unstable naphtha, light coking gas oil (LGGO), heavy coking gas oil (HCGO), and coke. The gas and the unstable naphtha produced in the delayed coking unit are sent to the gas recovery unit, for a greater recovery of liquid products. The HCGO and the product LCGO are sent to the heavy gas oil hydrocracking unit and the light oil hydrotreating unit, respectively, the coke is transferred to the coke loading unit for final handling and subsequent sale as fuel coke, anode or metallurgical. This process can be seen in the following Figure.

<center>https://steemitimages.com/DQmP827wP1ZYQ2Hhfg85W8kdzPLZw9MtBQNun1SbcQUXm3J/image.png</center><center>[Source](http://www.webaero.net/ingenieria/varios/Expo%20Industria/Industria/proceso_coquizac.htm)</center>

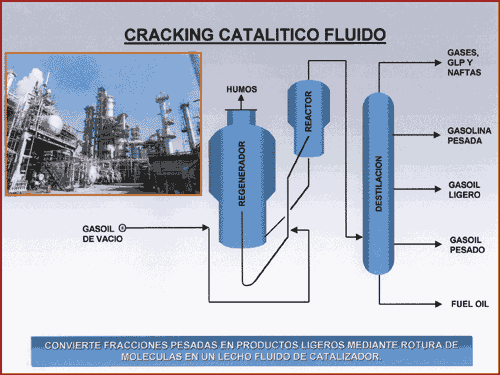

# Fluidcoking

This process is based on the handling of any hydrocarbon load that can be pumped. It is particularly adaptable to remove the high content of metals or carbon left in the waste of the treated cargo at temperatures of 1049 ºF or more in a vacuum plant. The obtained liquid products can be improved by hydrogenation. The crude coke that is achieved can be gasified. After removing the hydrogen sulphide, the gas can be used in the processing furnaces. In addition to the produced coke, the other lighter fractions produced can be processed in conventional treatment equipment.

<center></center>

<center>[Source](http://www.webaero.net/ingenieria/varios/Expo%20Industria/Industria/proc_catalit_flu.htm)</center>

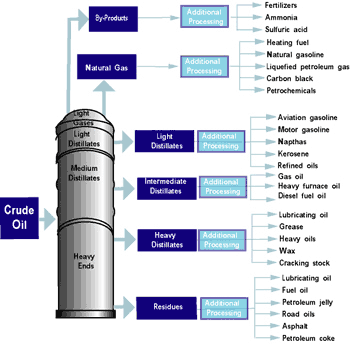

# Products Obtained Through Coking

## Gas

The gas produced in the coker is fed to a vapor recovery unit, where liquefied petroleum gas (LPG) and refinery fuel gas are produced. The LGP gas is treated with sulfuric acid and fuel gas and propane and burano are obtained, the LPG can be used as raw material for the alkylation or the polymerization unit.

## Naphtha

The light coke naphtha, after stabilization in the steam recovery unit, is often sweetened to reduce mercaptans and then sent to the gasoline pool. The heavy naphtha is hydrotreated and is used either as a raw material of the catalytic reformer or directly sent to the gasoline pool.

## Diesel oil

The coking light gas oil can be treated with hydrogen for color stabilization and used in the refinery as heating fuel. Heavy gas oil is commonly used as a raw material in the catalytic cracker or hydrocracker.

## Coke

It is a carbonaceous material produced from heavy fractions of petroleum, its physical appearance is hard, brittle, porous and grayish black. In relation to its chemical composition it is characterized by its high content of carbon, sulfur, metals (mainly vanadium and nickel) and ash.

<center></center><center>[Source](https://www.e-education.psu.edu/egee120/book/export/html/202)</center>

For more information visit the following links.

* https://www.e-education.psu.edu/egee120/book/export/html/202

* http://www.ingenieriaquimica.net/articulos/317-refino-del-petroleo-v-coking